Mechanism Synthesis

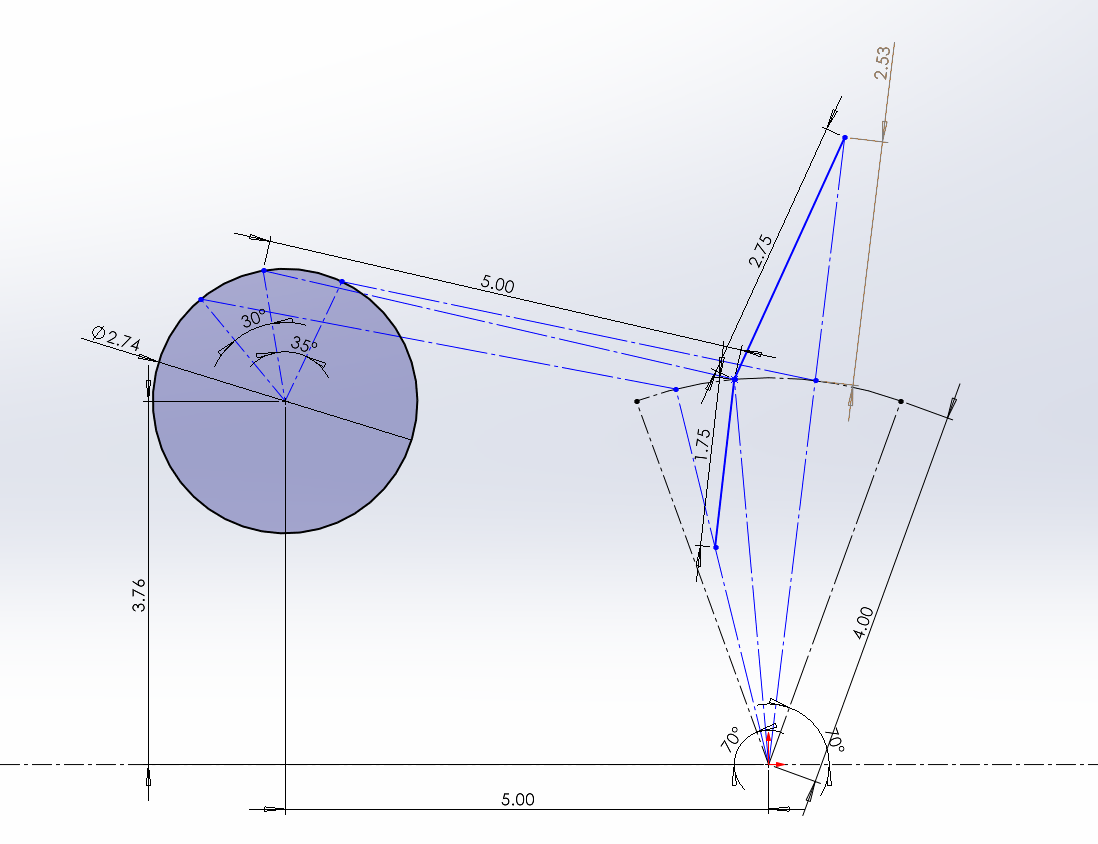

My mechanism uses a simple crank-rocker four bar linkage in order to maximize efficiency. While hydrofoilers have to pump into the water due to the asymmetry of gravity and their ability to produce power, motors have no such limitation. Using Solidworks to draft out an initial sketch using its built in constraints I was able to design a linkage that would barely fit into the channel of the boat. Initially, I wanted to create three phase-shifted rockers where the fin components would link in between them - that way, I wouldn’t need to depend on spring tuning and damping to achieve the desired motion. However, I found a lot of difficulty trying to route members and axles without them colliding. I ultimately settled on the somewhat simpler model I had now:

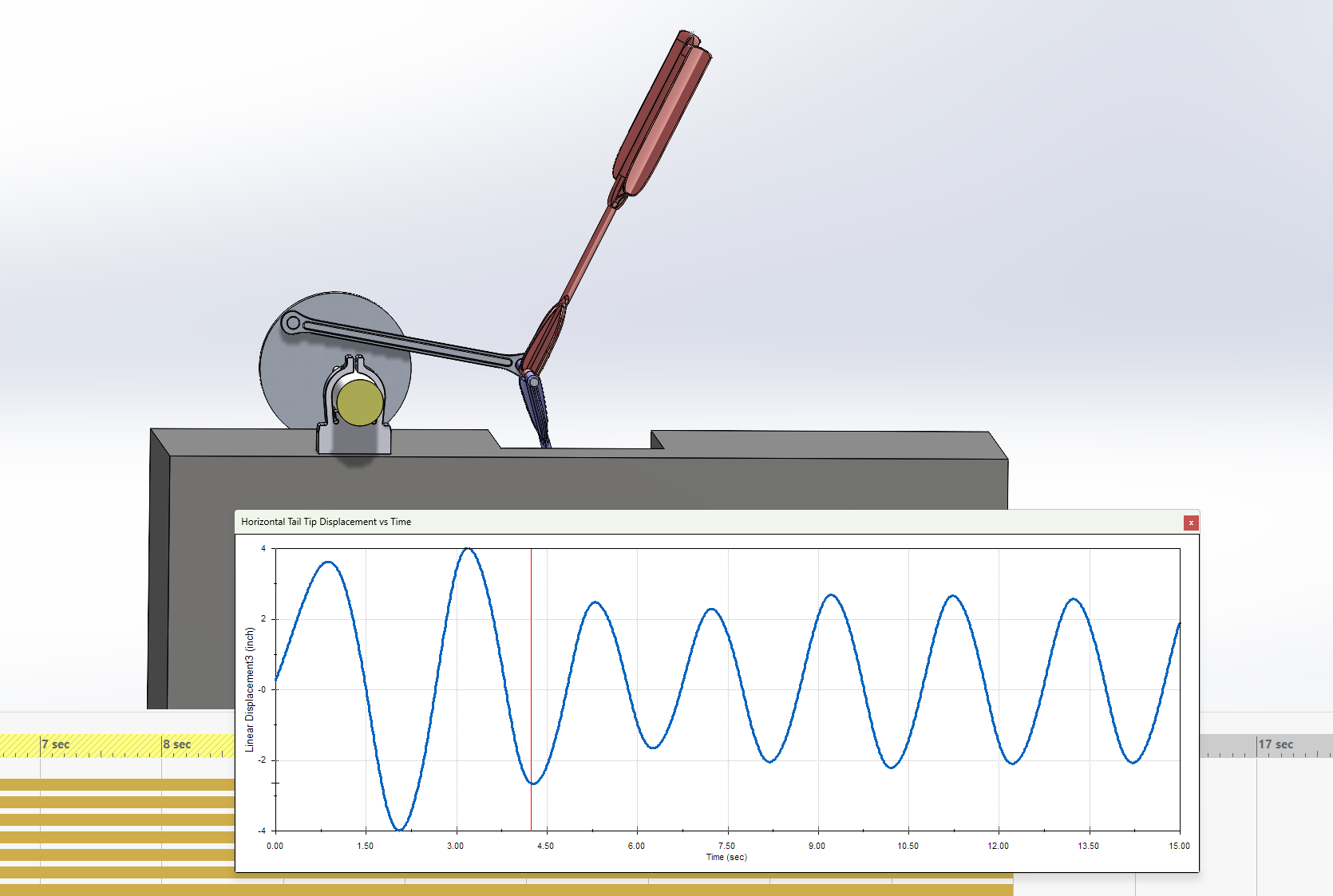

Spring Tuning and Motion Analysis

While challenging, I learned a great deal about how to choose the proper spring/dampening system for a mechanism. Eventually I realized that I needed to flex the spring at its resonant frequency in order to get the motion I was looking for. This meant constantly tweaking motor speeds, spring constants, and damping constants such that the mechanism wouldn’t wiggle uselessly or push water from side to side. I wanted the foils to cut through the water, minimally agitating it. After hours of trial and error I was able to find values that worked well within reasonable cycle speeds for usage of this scale in water.

Boat Propulsion Mechanism

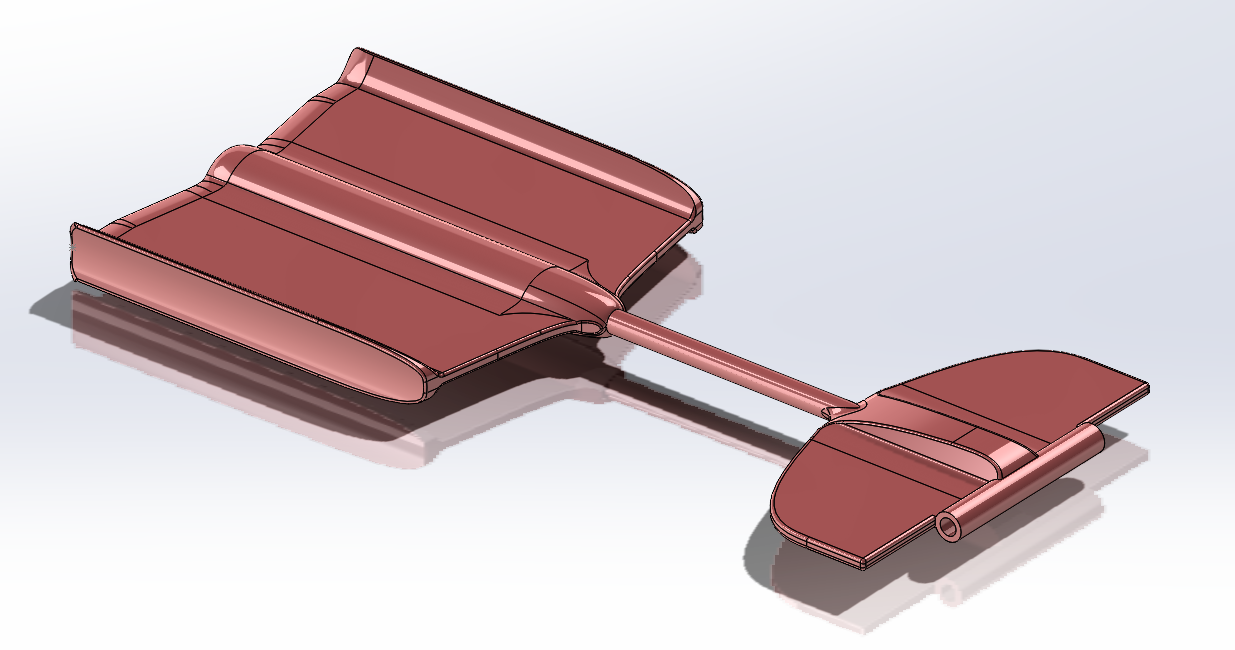

For this project we were tasked with creating a propeller-less propulsion mechanism for a small foam boat, with the idea that a linkage-based mechanism would be both less noisy and less endangering to wildlife who may come into contact with it. I ended up creating a two-piece swimming fin: driven by a crank-rocker four bar linkage, two rigid hydrofoils are held together by a torsion spring which allows them to flex slightly, propelling the boat through the water.

Design Inspiration: Fish and Hydrofoils

For my design I first looked toward nature; I was interested in finding out how I could emulate the biomechanics of a fish due to their undulating swimming patterns. After some googling I realized we’ve already invented ways to traverse water without propellers - namely swimming fins and hydrofoils. Both capitalize on an undulating motion and hydrodynamically shaped components.

Hydrofoil Design

This was one of the most challenging parts of the process, given I had limited experience with fluid/hydrodynamics and could only guess as to what aspects of the design I should emphasize. I spent a lot of time looking at the motion of the linkages and determining the ideal locations to put contact surfaces. I wanted to create a high-performance but theoretically manufacturable shape that would capitalize on the aspects of motion where the foil glides through the water, and minimizes wasted energy creating eddy currents and unnecessary drag. I picked a 3/16” pin diameter and 0.1” minimum feature thickness so that my design was still realistic. Since I don’t know how to design foils I used this assignment as an exercise in good CAD modeling practice, fully defining sketches, designing for changes to dimensions, and using symmetry where possible to my advantage.